|

Taizhou MIngsheng Mould Industry CO.,LTd

|

Gold Index: 3073

You are here: home > injection mold > 10L painting Bucket Mould

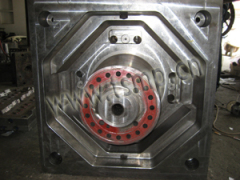

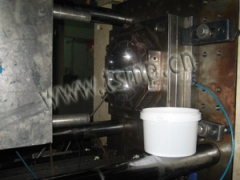

10L painting Bucket Mould

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Product:

Household Appliance

Shaping Mode:

Plastic Injection Mould

Product Material:

Plastic

10L painting Bucket Mould,10L painting Bucket Mold

1.Start with a product concept and determine measurements.

2.Draft plans, usually on a Computer Aided Design/Computer Aided Manufacturing (CAD/CAM) system in 2D and 3D models.

3.Analyze the production elements with software solutions, looking for areas of flow, dimension, and geometry that may cause problems such as high pressure fills, short shots, weld lines, poor cooling, part distortion, air traps, sink marks, bad gate locations, etc. May also run a working sample with 3D Printing, Stereolithography, or other system for rapid prototyping.

4.Cut the mold using Computer Numerical Control (CNC), Electrical Discharge Machines (EDM) or other methods. Determine the appropriate quality steel or aluminum for the appropriate mold class. Verify the product meets specifications.

5.Begin production.

2.Draft plans, usually on a Computer Aided Design/Computer Aided Manufacturing (CAD/CAM) system in 2D and 3D models.

3.Analyze the production elements with software solutions, looking for areas of flow, dimension, and geometry that may cause problems such as high pressure fills, short shots, weld lines, poor cooling, part distortion, air traps, sink marks, bad gate locations, etc. May also run a working sample with 3D Printing, Stereolithography, or other system for rapid prototyping.

4.Cut the mold using Computer Numerical Control (CNC), Electrical Discharge Machines (EDM) or other methods. Determine the appropriate quality steel or aluminum for the appropriate mold class. Verify the product meets specifications.

5.Begin production.

Related Search

Painting Bucket Mould

Bucket Mould

Ice Bucket Mould

Plastic Bucket Mould

Injection Plastic Bucket Mould

Injection Bucket Mould

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Taizhou MIngsheng Mould Industry CO.,LTd [China (Mainland)]

Business Type:Manufacturer

City: Taizhou

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (69)

- Encryption Products (1)

- compression tool (3)

- injection mold (56)

- Others (9)